Specifications

- Universal – unique variety of applications pre-shredding or making a sellable product with just one machine

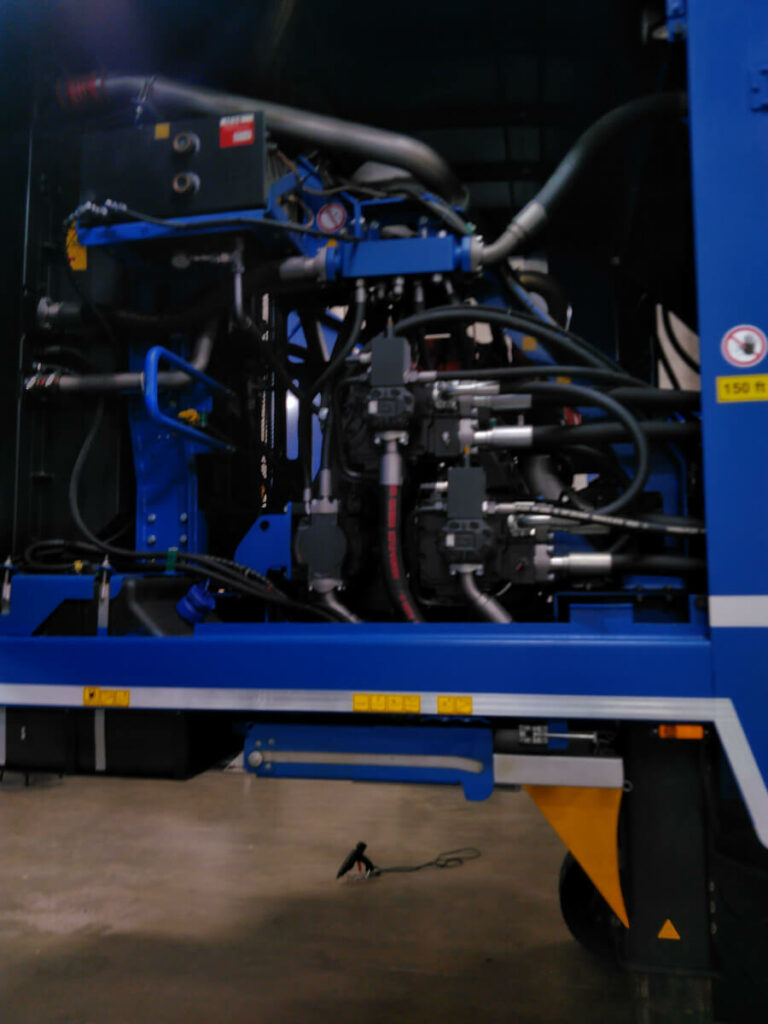

- Hydro-mechanical drive continuously variable control of rotor speed

- Simple – minimal maintenance effort, easy handling

- Eco-friendly – latest motor technology, lowest emissions

- Motor: 6 cylinder Diesel engine Cummins X15 (600 HP), oversized cooling system with reversible fan

- Control: IFM 7 “ Touch Panel + remote control with screen

- Rotor Diameter: max. 3.4 ft.

- Rotor Length: 10 ft.

Standard Features

- Tool-free adjustment of the cutting gap between the shaft and the comb sections for a quick change of the product size

- Increase of the hopper capacity from approx. 5.5 cu. yd. to approx. 9.5 cu. yd. when using the double-sided hopper extensions

- Easy access to the shredding compartment thanks to the hydraulically foldable comb door

- Large and wide conveyor belts for maximum material discharge

- Discharge height of rear conveyor up to max. 16.5 ft.

- Rear conveyor belt with infinitely adjustable height and speed

- MMS – Minimum Maintenance System

- Eggersmann Telematics System

- Hydro-mechanical rotor drive for the fastest reversing reaction and high resistance against contaminants

Additional Options

- Screening basket system underneath the shaft to make a specified and consistent product (3 to 10”)

- Neodymium cross belt magnet, hydraulically height adjustable, metal discharge to either side

- DURAMAX shredding rotor (special hard facing)

- Radio Remote Control

- Hydraulic drive of the wheeled machine to move it while using the remote control

- ECOSPRAY – Water spraying system

- Tool-free to mount hopper extension (16” high)

- Automatic lubrication system